charpy notch impact toughness test|charpy v notch testing requirements : manufacturer The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a . Resultado da Farm Heroes Saga, dos criadores de Candy Crush Soda Saga e Bubble Witch 3 Saga! O guaxinim Rançoso está tentando aprontar por aqui, roubando o máximo de Cultivinhos que conseguir. Junte-se aos Heróis da Fazenda e ajude-os a coletar os Cultivinhos para salvar o dia! Divirta-se .

{plog:ftitle_list}

Resultado da bet365 - A casa de apostas online mais popular do mundo. Oferecemos o serviço Ao-Vivo mais completo. Assista Esportes Ao-Vivo. Transmissão .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness . What Is the Charpy Impact Test? The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to .

The Charpy V-notch test is used worldwide to indicate the ductile-to-brittle transition of a steel. While Charpy results cannot be directly applied to structural design requirements, a number of correlations have been made between Charpy results and fracture toughness. Impact Toughness Testing of Metals. satyendra; December 7, 2016; 1 Comment ; Charpy V notch test, Drop weight tear test, Drop weight test, fracture, fracture analysis, impact strength, Impact toughness, Instrumented charpy test, izod test,; Impact Toughness Testing of Metals. Metals undergo dynamic fracture under rapidly applied loads which are generally .

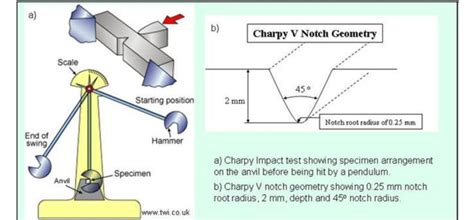

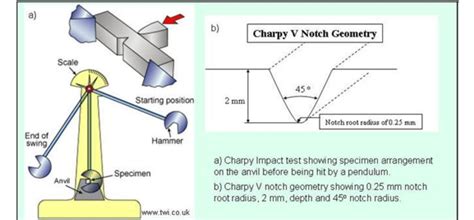

Measuring Toughness – Impact Tests. As was written, toughness can be measured by the Charpy test or the Izod test. These two standardized impact tests, the Charpy and the Izod, are used to measure the impact energy (sometimes also termed notch toughness). The Charpy V-notch (CVN) technique is most commonly used. Both of these tests use a . The “standard” notch used in the Charpy impact test is the 2 mm deep V-notch with a 0.25 mm root radius, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm.

Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018) : Plastics — Determination of Izod pendulum impact resistance ISO 180:2019 : Plastics — Determination of Izod impact strength Charpy impact testing determines the impact energy of materials. . The Charpy test is most commonly used to evaluate the relative toughness or impact toughness of materials and as such is often used in quality control applications where it is a fast and economical test. . A 5mm deep notch with 1mm radius at the base of the notch. What Does .The Charpy-V test for characterising notch toughness is described. The qualitative nature of the test, outline procedures and test analysis are described. . However, in the context of an impact test we are looking at notch toughness, a measure of the metal's resistance to brittle or fast fracture in the presence of a flaw or notch and fast .

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . This absorbed energy is a measure of a given material’s notch toughness and acts as a tool to study temperature-dependent ductile-brittle transition.

The Izod impact strength test is an ASTM standard method . A notched sample is generally used to determine impact energy and notch sensitivity. The test is similar to the Charpy impact test but uses a different arrangement of the specimen under test. [1] The Izod impact test differs from the Charpy impact test in that the sample is held in a .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the .

Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact .

How is the Charpy Impact Test performed? In a Charpy impact test, a notched (U-notch, V-notch, and double notched) material specimen is clamped in a test apparatus, and a pendulum is released to strike the notched area. The energy . The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. It must be noted, however, that the Charpy test is less useful for comparing the toughness of different metals but is more suited to providing information on the behavior of a single material at . This paper presents the results of the Charpy V-Notch (CVN) impact test for the ST, TL, TS, LS, LT, 45°, and SL directions in API 5L X52 pipelines with electric-resistance-welded (ERW) and .

charpy v notch toughness

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

Charpy Impact Testing, also known as the “Charpy V-notch test,” is a standardized test method used to determine the impact toughness of materials, particularly metals. It assesses a material's ability to absorb energy during fracture when subjected to a sudden impact.Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces. On the other hand, due to simple operability of the impact test, the relation between impact toughness and fracture toughness has been investigated over the past decades. Rolfe-Novak-Barson [10], [11] established an empirical formula between Charpy impact energy and fracture toughness through analyzing numerous steels with different strength .

Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

Toughness may be anisotropic, and the Charpy impact test is one method to measure impact toughness . Some studies have determined pipeline toughness and anisotropy by testing Charpy specimens in different directions with respect to the RD, obtaining excellent results [10,11,12,13,14]. However, only some Charpy V-notch (CVN) values have been . The Instrumented Charpy impact test is a promising method for determining a material’s impact response. Stainless steel has higher impact energy absorption capacity, high tensile, and yield . Charpy Impact Test. The Charpy test is less commonly used than the IZOD test and results in a measurement of absorbed Charpy V impact energy, in Joules. . Stress concentration is a major factor in material strength. A sharp-tipped notch will promote fracture by focusing the stress at a point, so notch radius is critically important in .

charpy v notch testing standard

ninfeta vazou. (1,532 results) brazillian bull, Realizador Baiano fudendo pretinha infinity com muito tesão. Festinha liberal acabou com Realizador Baiano no quarto e uma .

charpy notch impact toughness test|charpy v notch testing requirements